Discover TrooRa Marketplace, Shop New Products Open NOW!

The Perfectionist

Written by: Robyn Alexander

Rock-star chef Gregory Czarnecki

Rock-star chef Gregory Czarnecki has secret skills that only a select few know about—anyone lucky enough to try his mind-blowing, guess-the-flavour bonbons will never go back to eating just any chocolate

A spray-gun and a hairdryer. They don’t sound like usual tools in the arsenal of a professional chocolatier, but then again, ‘usual’ is not a word anyone who knows or works with Gregory Czarnecki would use to describe him. In fact, the award-winning, French-born chef doesn’t even call himself a chocolatier.

“I didn’t study it, it’s not my job,” he explains as he sprays a fine mist of vivid orange cocoa butter into a chocolate mold, occasionally using the hairdryer to warm up the mixture when it becomes too thick. This is how he creates the delicate shells of his bonbons, but he says a home cook could use a small paintbrush to thinly paint the cocoa butter onto the molds, then use a toothpick to create any pattern, zigzag or swirl, followed by a second layer of cocoa butter in another colour to fill in the lines.

So if making chocolate is not his job, it must be a passion then? A calling? Why else would he spend two days a week crafting his astonishing chocolates for diners at The Restaurant at Waterkloof? Gregory has headed up the kitchen for the past ten years, but it was only four years ago that he decided to start making the edible works of art that have since become a fixture at the end of his 15-course degustation menu.

Leah Alexander

“I was one of the first people to bring the bonbon to this country—I wanted to offer diners something different,” says Gregory. “I am self-taught. Yes, I did work with chocolate when I was an apprentice but now I guess I have more knowledge, more patience, less arrogance. And I decided that if I was going to make chocolates, they would have to be the best-looking ones I could possibly make. I want to look at them and be proud to have spent so much time on it. For me, it’s the results that matter.”

And it’s the imaginative results of his experiments in colour and flavour that almost defy description. The themed collections of five bonbons per table of two change constantly and can include gleaming black pyramids and gemstones, marble-like stones in neutral hues, or swirls of yellow, turquoise, and purple. Concealed beneath their mirror-like cocoa butter shells are ganache fillings in some rather way-out flavour combinations.

chef Gregory Czarnecki

If for some reason, the hazelnut and parmesan or passion fruit and basil oil do not fascinate you, perhaps the crème fraiche and raspberry vinegar will. What’s more, their creator takes great delight in tricking the senses—the exteriors of Gregory’s bonbons give no clue to what diners’ taste buds will experience. “I always make sure that the colour on the outside doesn’t match the flavour. Why do yellow if it’s lemon, you know? You want people to be intrigued, to have to figure it out.”

I decided that if I was going to make chocolates, they would have to be the best-looking ones I could possibly make. I want to look at them and be proud to have spent so much time on it. For me, it’s the results that matter. – Gregory Czarnecki

Office Interior

Interior- Dining room

chef Gregory Czarnecki Cocoa Loco

chef Gregory Czarnecki bonbons

A no-limits attitude, a powerful streak of perfectionism, and using only the best-quality chocolate as the star ingredient—which he works with at precisely controlled temperatures—are the key to his edible works of art. “If you just melt chocolate, like people do when they want to dip strawberries, you’re not going to end up with a snappy chocolate. You have to bring it to a higher temperature, quickly lower it, then warm it up again so that you can work with it. There are specific temperatures, depending on the amount of bitterness, origin, and type of chocolate you are using.”

When the chocolate has been expertly tempered, it is poured into the molds over the set cocoa butter shells. Once the chocolate has had a chance to set, Gregory uses a piping bag to add the ganache filling, taking care not to overfill each mold. The ganache is then left to set at room temperature for 24 hours. Now comes the final touch, a last layer of tempered chocolate to seal the deal.

Master Bathroom

chef Gregory Czarnecki bonbons

Gregory’s meticulously created bonbons are then de-molded and stored in a special room at 7˚C until two hours before they are to be served, at which point they are transferred to another room at 14˚C—his advice on the perfect temperature at which chocolate should be served for maximum flavour.

Exactly two hours after diners first embark on their culinary journey, they will, at last, receive their bonbons presented in a box bearing Gregory’s logo. “I even bought the machine that makes the thermoplastic sheets they are arranged on. Sure, there are places that can make the sheets for me, but they want you to order thousands and maybe I just want 100. Now that I have the machine, I can do anything with it, you know.”

Indeed he can! ![]()

TrooRa Magazine

Words

Cristina Deptula

California, USA

Welcome to TrooRa Magazine

Already registered Sign In

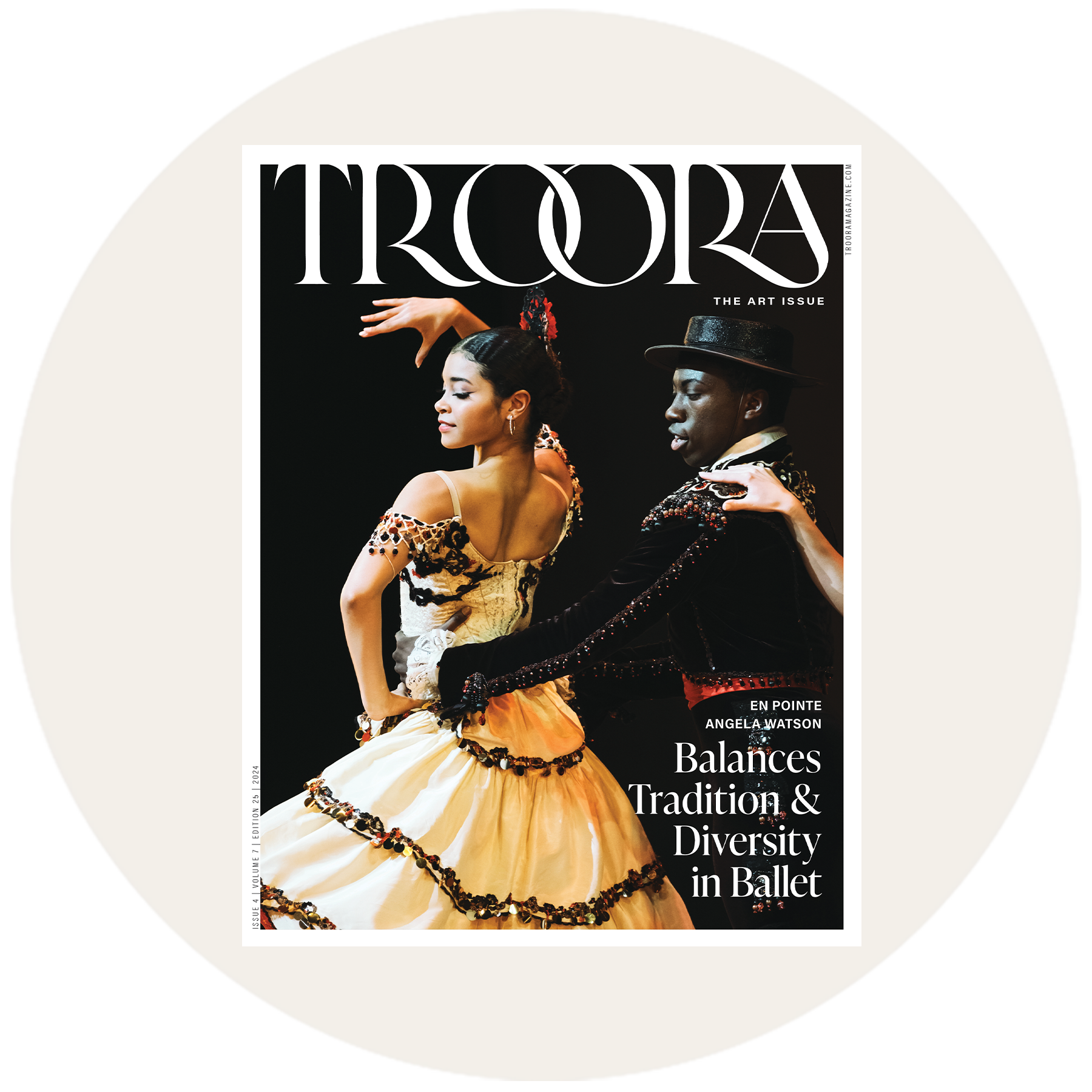

Art Issue 2024 Edition 25

Marking a milestone with our 25th issue, TrooRa Magazine’s Art Issue 2024 (Special Edition) explores the transformative power of creativity as a force for healing, unity, and change.